Ensuring the cleanliness of wire shelving is paramount in commercial environments, ranging from bustling restaurant kitchens to well-organized hotel storage facilities and crucial hospital supply rooms. The open design of wire shelves provides optimal air circulation, making them a popular and practical choice in these settings. However, the accumulation of dust and debris over time can compromise hygiene standards. This comprehensive guide will not only underscore the importance of cleanliness but also walk you through the detailed steps required to efficiently clean wire shelving in diverse commercial spaces, ensuring they consistently meet the stringent cleanliness requirements of these environments.

What is wire shelving?

Wire shelving systems play a pivotal role in various commercial spaces, such as restaurant kitchens, hotel storage areas, and hospital supply rooms. The benefits of wire shelving cannot be overstated. Renowned for their sturdy construction and the ability to accommodate heavy and bulky items, wire shelving systems are essential for businesses that demand robust and hygienic storage conditions. Their breathability and cleanliness are critical considerations, setting them apart from alternatives like wood shelves and solid metal shelves. Unlike these alternatives, wire shelving provides optimal ventilation, keeping stored goods fresh and preventing the buildup of harmful bacteria and other pathogens that could compromise products or risk workers’ health. Their open design facilitates air circulation, preventing moisture buildup and maintaining a clean and organized storage environment. Additionally, wire shelving is known for its adaptability and customizability, easily configured to meet specific needs, whether storing various-sized items or maximizing vertical space by adding extra wire shelving.

However, despite these advantages, the exposed nature of wire shelves makes them susceptible to the accumulation of loose dust and debris.

Why should you clean wire shelving regularly?

Regular cleaning of wire shelving is not merely about maintaining the aesthetic appeal of your storage spaces but also about extending the life of the shelves themselves. The accumulation of dust, grime, and sticky residue can corrode the coating on wire shelves which will compromise the integrity of the shelving, potentially impacting the hygiene of stored items—whether it’s kitchen supplies in a restaurant, linens in a hotel storage room, or medical supplies in a hospital.

Preparing the Space for a Thorough Wire Shelving Cleaning

Before initiating the cleaning process, meticulous preparation of the area is crucial:

Safely Removing Items from the Shelves

Remove all items from the wire shelves, ensuring a thorough cleaning. It’s vital to do this safely, not carrying more than you can reasonably handle.

Relocating the Shelves to an Accessible Area

If feasible, relocate the shelving to an area where you can easily clean all sides. This step ensures effective rinsing and drying of the shelves from all angles.

Tools and Supplies Needed for Cleaning Wire Shelving

To effectively clean your wire shelves, you’ll need an array of tools and supplies:

Industrial-Grade Vacuum Cleaner

An industrial-grade vacuum cleaner equipped with a brush attachment is ideal for removing loose dust and debris from the entire wire shelf, especially from hard-to-reach corners.

Dry Paper Towel or Microfiber Cloth

When it comes to removing loose dust from your wire shelving, the choice of your cleaning tools can make a significant difference. Opt for a dry paper towel, duster, or microfiber cloth for this initial step in the cleaning process. These materials are not only gentle on the surface of the shelves but also effective in capturing and lifting away loose particles without causing any abrasion.

Dish Soap or Mild Detergent

Dish soap is effective for tackling tougher grime and grease, particularly in kitchen pantries where shelves might accumulate cooking residues. A bucket with mild detergent can be used to wipe down the shelf with a soft cloth or sponge.

Spray Bottle

A spray bottle facilitates the even application of your cleaning solution across the shelving.

Damp Sponge

After applying the chosen cleaning solution to your wire shelving, a damp sponge becomes an invaluable tool for the next phase of the cleaning process. The damp sponge serves multiple purposes, elevating the effectiveness of the cleaning solution and ensuring a thorough and streak-free finish on your shelves.

The dampness of the sponge aids in the removal of any residual cleaning solution, ensuring that no sticky residue is left behind. This step is vital, especially in commercial spaces where hygiene standards are paramount. By meticulously wiping down the shelves with a damp sponge, you not only eliminate any remaining traces of the cleaning solution but also contribute to the prevention of sticky wire shelves, a common issue that arises when excess cleaning agents are left to dry.

Rinse and Dry Process

Rinsing and drying are two crucial components of the cleaning process and are often overlooked. Ensuring there is no moisture or chemical residue left on the shelves is essential to prevent the development of sticky wire shelves, which can eventually lead to damage and corrosion.

A Note on What Not to Do

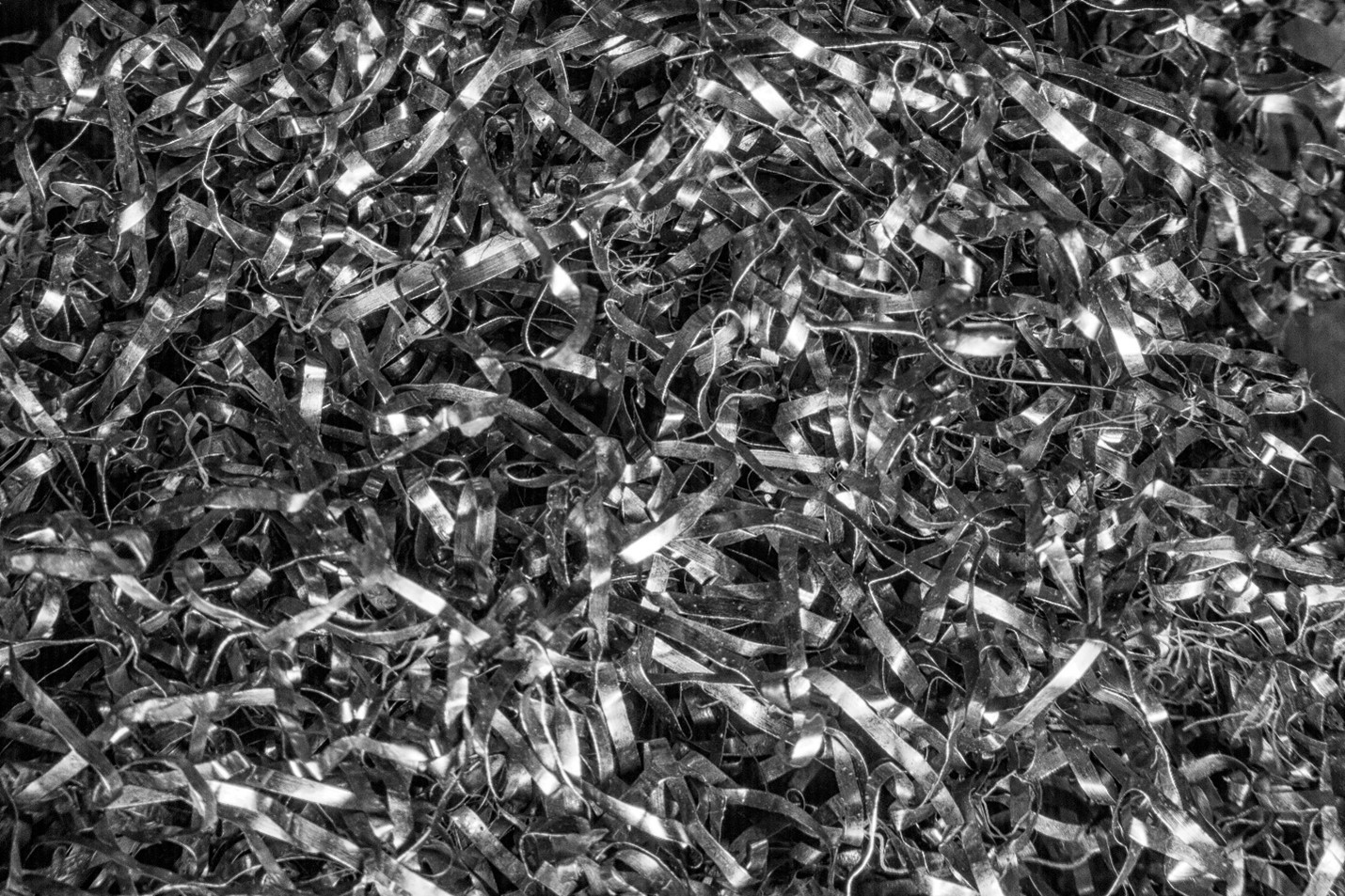

While wire shelving is robust and versatile, it requires careful cleaning to maintain its longevity. One crucial caveat with wire shelving is to avoid using anything abrasive during the cleaning process. Abrasive materials, such as steel wool or harsh scouring pads, can compromise the integrity of the wire shelving in several ways.

Abrasive materials have the potential to strip away the protective layers on the surface of the wire shelves. These layers are designed to shield the shelves from environmental factors, including moisture and contaminants. When these protective layers are removed, the wire shelves become more susceptible to corrosion and damage.

Moreover, the abrasive action of materials like steel wool can create scratches on the surface of the shelves. These scratches not only mar the aesthetic appeal of the shelving but also create crevices where moisture and grime can accumulate. Over time, this trapped debris can contribute to the degradation of the wire shelves, accelerating the corrosion process and potentially shortening the lifespan of the shelving.

Conclusion:

In conclusion, the upkeep of wire shelving in commercial spaces demands diligence and attention to detail. By understanding the significance of wire shelving and following the comprehensive cleaning guide provided, businesses can ensure not only the longevity of their shelving but also maintain optimal hygiene in environments ranging from bustling kitchens to critical medical supply rooms. Regular maintenance and careful cleaning practices will not only preserve the aesthetic appeal of storage spaces but also uphold the integrity of stored items, ultimately contributing to a healthier and more organized commercial setting.

+1 (905) 825 9665

+1 (905) 825 9665